Last fall, Nikki and Natalia traveled to Portugal for five days. There, they met with some of our current production partners, explored new opportunities, and learned more about ways our production can be more sustainable. Below is a quick recap of their factory visits, where they saw how the products are made and the exciting new developments for future seasons 🙂.

For those who may not know, 100% of our tees and sweats are made in Portugal. There, we have the most incredible partners that Nikki visits every year. Nikki and Natalia’s daily schedule consisted of driving a rental car to the surrounding cities of Barcelos, Braga, and Guimarães using GPS and speaking no Portuguese whatsoever 🤪. At the factories, they went over current production (Spring 2023), worked on future developments (Fall/Winter 2023), and reviewed our overall sustainability practices. Throughout the trip, they visited dye houses, wash houses, and embroidery houses, as well as knitting facilities, with a few cheese plates in between 🧀.

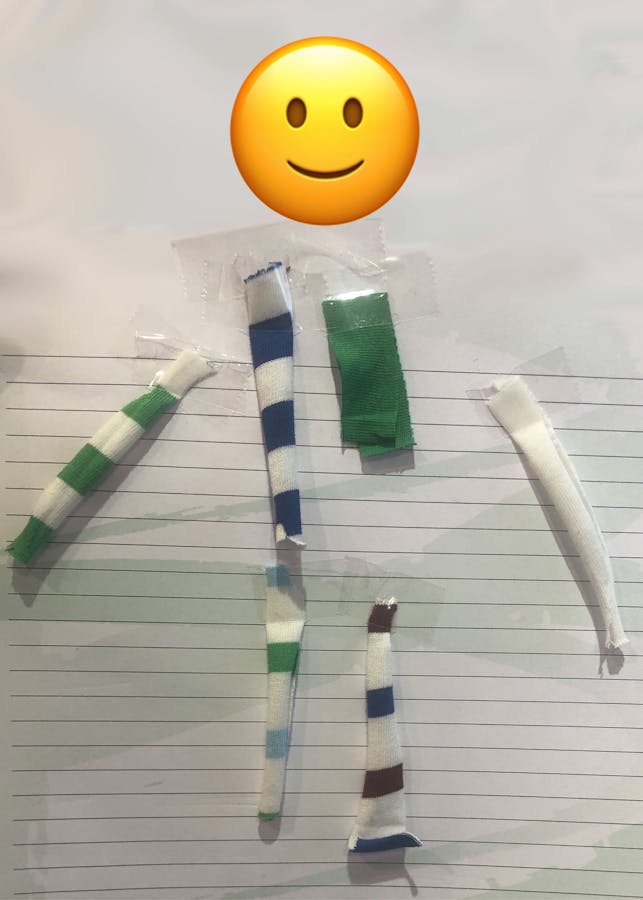

At the end of every season, Nikki reviews our fabric inventory. She creatively repurposes this fabric into our fun patchwork rugbies, reducing KULE’s fabric waste by giving this leftover fabric a new life.

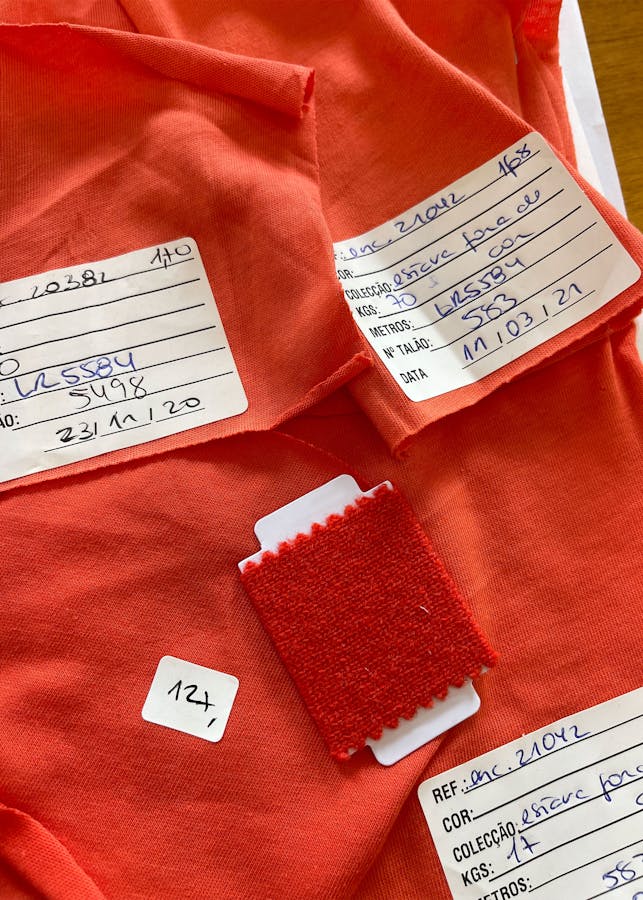

Later in the day, they reviewed our current production’s cutting, sewing and lab dips. We are so excited to show you what the factories are making right now 👀. Stay tuned for Spring 2023!

One of the highlights was visiting the knitting factory to check out the production of our Malibu featherweight tee to restock for Oprah’s Favorite Things 🙂. Our featherweight tees are truly special, made from a custom fabric by our mill partner for KULE. They are made of the lightest-weight fabric that can be knit into yarn-dyed stripes. Therefore, the fabric is very delicate and must be carefully managed to avoid snags and twists in production. Due to its fine nature, the pattern pieces must be cut by hand so the stripes perfectly match up on your tees.

They also visited the dye house where all of the products are washed and put through an intense process of fabric quality testing. Nikki and Natalia went on a tour to learn about the ZDHC certification process. To be certified, the factory must reuse at least 10% of the water and is always trying to reuse more. ZDHC factories limit hazardous waste from their practices. They work with their local community to clean the water so that the water they’re sending back out is safe. Very few factories are ZDHC certified. This dye house is also partially solar-paneled for as low-impact electricity as possible.

A lot of the surrounding factories are on farms that grow vegetables and herbs for themselves, the workers, and to sell. It’s a great use of the beautiful land.

As for new developments… KULE has some really exciting things in the works which you’ll have to wait and see, but here’s a sneak peek…

And it wasn’t all business. Nikki and Natalia made room for lots and lots of great food and sights, too. Portugal is so beautiful.

Overall this trip was very successful. They loved looking at the new developments and all the endless possibilities. Stay tuned for the exciting new product they had the pleasure to see made for our upcoming collections 🙂. Until next year, Portugal! Obrigada! 🇵🇹❤️